Made in Bushwick: Inside the Knickerbocker Manufacturing Company

Photos by Jane Bruce

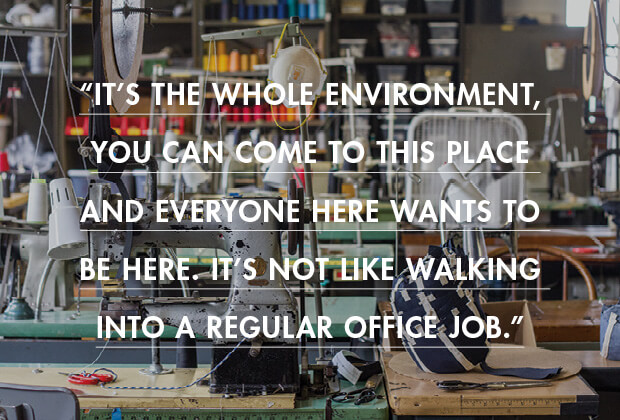

The Knickerbocker Manufacturing Company sits on the outskirts of Bushwick. Much like the other industrial buildings peppering the surrounding area, it has a nondescript brick facade, but something unexpected lies behind Knickerbocker’s heavy doors: a skateboard ramp. The half-pipe sits prominently inside the front entrance of the factory floor, serving as something of a break room activity for staffers of the menswear brand. For some, the presence of a skateboard ramp might come as a surprise, but for those who know Andrew Livingston, the company’s 23-year-old founder, a work environment without such features wouldn’t make much sense.

Livingston, who grew up skating and surfing, was a national champion snowboarder at the age of thirteen, and early on demonstrated an interest in fashion, starting his first clothing company while in college at New York University. Notably, the brand was named Ferris, after one of cinema’s most-loved youthful troublemakers, Ferris Bueller.

Fellow NYU-alum and current Knickerbocker employee Luis Paladino recalls a time when Livingston’s dorm room was cluttered with boxes of Ferris T-shirts: “Shipments of boxes of tees would show up and he’d sling them out of the college dorm room.” To hear him tell it, it’s a scene not dissimilar to the humble NYU-dorm beginnings of Def Jam Records.

Shortly afterward, Livingston’s ambitions for business outweighed his commitment to school. He took time off following his first year of NYU in order to focus on Ferris, and opened up a retail location in Williamsburg. Soon enough though, Livingston dropped out entirely when a golden opportunity appeared: the purchase of a defunct 60-year-old manufacturing business. The Brooklyn-based Watman Headwear Corporation had recently met its demise, but was still frequented by designers who used its aging machinery to make their own goods. After Livingston spent some time making hats at the factory, he discovered that the owner, Steven Watman, would sell him the space. Watman’s asking price was a paltry sum for what was not only a sprawling facility, but all the machinery that came with it.

Livingston and two friends, Daniel McRorie and Kyle Mosholder, organized a Kickstarter to raise funds for the factory purchase, which surpassed its $15,000 goal—the total price Watman wanted for the factory—and in June 2013, Knickerbocker was born as a private label manufacturer.

Livingston soon found himself transitioning into the life of a factory owner. He had limited experience in actual clothing production: He had worked at Billabong, the action sports clothing company, in his teenage years, but claims he “didn’t learn shit… You have to figure out the hard part on your own.”

For Livingston, running Knickerbocker has gone beyond simply dusting off the factory’s old machines and firing them up for use; it involves developing a larger operating ethos for his company.

Livingston believes outsourced labor is a uniformly bad thing in global economics. “The whole supply chain is totally messed up when you look at labor conditions, wages,” he says, adding that any company with factory holdings in the third world is actively “supporting that whole supply chain.”

But despite the fact that domestic manufacturing is a part of the brand’s DNA, it’s not something Livingston likes to glorify. In fact, he gets fired up when discussing other brands that trumpet their “Made in the USA” bona fides. He feels it’s dishonest.

“When people use that from a really obvious marketing standpoint, it always shows through,” Livingston says. “It’s still not genuine; it’s not unique. You’re not doing that because you care; you’re doing it for all the wrong reasons.”

Of course, largely because they produce everything in the US, Knickerbocker’s goods are on the more expensive side—but customers get what they pay for. All carefully crafted, Knickerbocker products are an extension of Livingston’s belief in healthy, stable labor environments—and, also, he says, “It’s just timeless, classic stuff.” What that means is, garments are always “black, tan, navy, and olive,” tailored to a vintage American look, and usually reference America’s industrial past, with items like engineering vests, service shirts, and work hats forming much of Knickerbocker’s catalog.

And speaking of work hats, the young company has only eight full-time employees, so Livingston assumes numerous professional roles himself. “You’ve got to be a designer, debt collector, accountant… I’ve got retailers owing me tons of money right now,” he says in his office, pointing at his computer, as if fighting for survival is a routine part of his job.

“I’ve been screwed by a lot of retailers. That’s how it goes, it’s tough.”

But Knickerbocker makes enough to survive, largely because it exists as much as a playground for design as it does a clothing company. For company employee Brian Blakely, the spirit of the place is what undergirds its momentum.

“It’s the whole environment. You can come to this place and everyone here wants to be here. It’s not like walking into a regular office job,” Blakely says.

That’s partly because Livingston lets aspiring designers use the machines at Knickerbocker to work on their own projects. It’s his way of giving back to people who probably won’t have the chance to acquire an entire factory for just $15,000.

“People come in here and we teach them and they learn and they go and make their own stuff,” he says. In that way, Knickerbocker can be viewed as a potential breeding ground for a crop of New York’s forthcoming designers.

When looking toward the future, Livingston can’t be sure what lies immediately in Knickerbocker’s path. But if the praise of his coworkers is any indication of what’s to come, Livingston’s ambition and diligence only dictate further success.

As Livingston’s college buddy Paladino—who, unlike Livingston, graduated, and now works beneath his former classmate, says, “Just the fact that he dropped out but remained so motivated… that he’s now my boss—and I graduated,” is something that makes Paladino laugh.

But Livingston shrugs off the compliments, looking at the ground instead. He says, “It’s already come a lot further than I thought it would have by now.”

You might also like